- Carbon Steel Auto Parts Precision Casting

- Carbon steel automobile brake system parts casting

- Automobile carbon steel precision parts castings

- Precision casting of carbon steel auto brake parts

- Carbon Steel Auto Engine Parts Precision Casting

- High speed train carbon steel connecting rod castings

- Coated Sand Steel Castings

- Automobile and motorcycle stainless steel parts precision castings

- Stainless Steel Auto Parts Castings

- Stainless Steel Ship Castings

- Stainless steel auto spring seat precision casting

- Stainless Steel Brake Disc Casting Processing

- Railway Press Plate Alloy Steel Castings

- Automobile balance frame alloy steel precision casting

- Automobile drive shaft alloy steel precision casting

- High speed train alloy steel connecting rod castings

- Alloy auto parts precision castings

- Heat-Resistant Steel Centrifugal Cast Tube

- Axle parts casting

- Powerful wrench precision castings

- Knocking wrench precision casting

- Ship accessories casting

- Automobile suspension lug castings

- Low Speed Lever Precision Casting

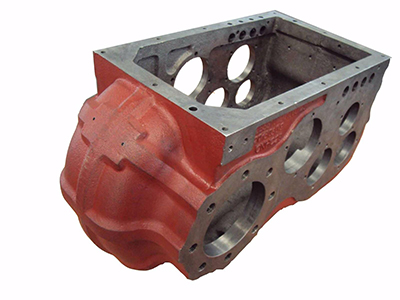

Garway box casting

Call : +86 13390692151

sale@kfqizhongji.com

Lost foam casting adopts mechanical, hydraulic, pneumatic and electronic control methods, self-designed domestic production line, the number of sandboxes is more than 10-50, with sand cooling system equipment, annual production scale of 2000-30, 000 tons, investment of 50-4 million yuan.

This kind of production plant is characterized by the completion of the system, complete functions, one after another work, appropriate mass production, mass production of lost foam iron castings production process is a lot of equipment to form a large production line.

The reasonable arrangement of the production line can avoid some expenses between the equipment and the equipment.

Reducing unnecessary waste of lost foam castings, shortening the distance of logistics channels in the workshop, improving production efficiency, reducing production costs, effective use of resources, and even reasonable layout of production lines are conducive to the full play of the production process.

Lost foam casting is a new process with almost no margin and precise molding, which does not need mold, parting surface and sand core, and the casting has no burr, burr and drawing angle, which reduces the dimensional error caused by the combination of die core.

The surface roughness of stainless steel castings can reach Ra3.2-12.5m, the dimensional accuracy of stainless steel castings can reach CT7-9, and the machining allowance can reach 1.5-2mm, which can greatly reduce the processing cost.

Lost foam casting is a new casting method, in which the parts are buried in dry quartz sand by vibration forming and poured under negative pressure. Lost foam casting, nodular cast iron casting and stainless steel casting gasify the model, and liquid metal occupies the position of the model.

Lost foam casting (EPC) is a new precision-dense casting process with almost no margin.

It combines paraffin or foam models with castings of similar size and shape to form a model cluster.

In this process, there is no mold, no parting surface, no sand core, and no flash edge, burr and draft angle of the casting, which reduces the dimensional error caused by the combination of the core.

It provides rich degrees of freedom for the structural design of castings.

The combination of foam modules can produce highly complex castings.

The non-radical casting core will not lead to uneven wall thickness due to the inaccurate size of the core or the low position of the radial casting core.