- What are the determination methods of stainless steel precision casting?

- Basic requirements of stainless steel precision casting casting structure

- Requirements for moulds of steel castings foundry manufacturers

- What are the models of ductile iron castings?

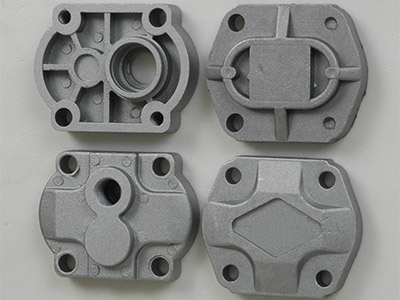

- Manufacture and Application of Aluminum Alloy Die Castings

- Basic procedures for stainless steel precision casting

- What are the advantages of lost foam casting

- Effectively improve the quality in the process of cast steel production

- Stainless steel precision forged process measures below

- Difficulties of stainless steel precision casting processing

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

How to choose suitable cast steel parts

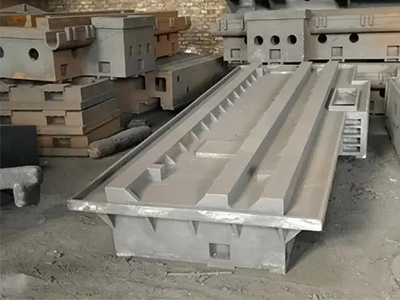

Nowadays, with the increasing demand for castings, large steel castings manufacturers come to talk to you about how to find suitable steel castings for manufacturers. Steel castings are no stranger to everyone now, from small to dozens of grams, up to hundreds of tons, it is not easy for users to find suitable castings.

First, when choosing steel castings, users need to be clear and understand the shortcomings of steel castings. For example, when casting steel bars, it is easy to organize the parts unevenly, the blank surface of steel castings is generally rough, and its shape is more complex. Manufacturers have relative responses to these defects, such as: in view of uneven casting structure, manufacturers will allow technicians to scientifically and reasonably design processes and processes, control casting pouring time, etc.; in the face of large steel castings with rough surface, users can choose manufacturers that can integrate casting and processing to carry out machining to save time and money.

Second, we also need to know the advantages of steel castings. For example, the greatest advantage of steel castings is their high flexibility. Manufacturers are free to design the size and shape of castings, especially those with complex or intermediate cross-section; forming and changing shape are also simple and fast, so it is convenient for manufacturers to quote and deliver quickly; the weight can be done from tens of grams to hundreds of tons; the isotropy of steel casting materials and the overall structure of steel castings are very strong, so the reliability of the project is improved. Steel castings have competitive advantages in terms of price and economy.

Therefore, what large steel casting manufacturers want to say is to understand whether their industry needs steel castings through the advantages and disadvantages of steel castings, and make the right choice, such as size and weight.