- Process Classification of Precision casting

- The primary condition of the precision casting gear

- What are the common measurement problems of stainless steel castings?

- Application of Heat Treatment Gear Castings

- How to adjust the furnace fire cast by stainless steel?

- What is the tempering treatment of stainless steel precision casting?

- What should I pay attention to in the production process of stainless steel casting?

- Practical significance of pump casting to pump

- Why should the quality of steel casting pay attention to good molds

- Factors that cause precision casting size defects

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

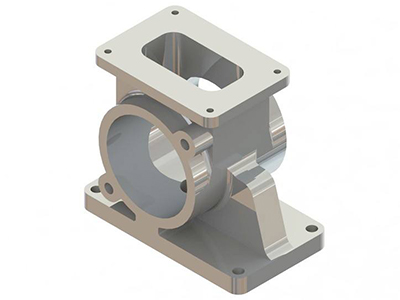

Structural characteristics of machine tool casting

Although there are many kinds of machine tool castings, from the point of view of casting technology, there are mainly the following characteristics in structure: although there are many kinds of machine tool castings, from the point of view of casting technology, there are mainly some characteristics in structure:

1) the basic parts of machine tool castings are box-shaped structures, and many reinforcements are added, so that the structural shape of the castings is more complex. More cores are needed in casting, and core braces are often used to fix the core; during pouring, the gas produced by the core is also difficult to remove, which is easy to produce defects such as stomata and sand holes.

2) some parts of the casting, such as guide rail surface, shaft hole and T-groove (after increasing machining allowance), are thicker, which is not only easy to produce shrinkage cavity and porosity, but also because the properties of cast iron are sensitive to wall thickness, and it is easy to make the structure loose, graphite coarse, low hardness and not wear-resistant.

When the thickness of these parts is too different from the surrounding connecting wall, it is easy to produce cracks and other defects.

3) some castings under oil pressure and cutting fluid pressure are required to have high air tightness and leakage is not allowed.

4) due to the development of automatic, high-speed and strong cutting, the emergence of CNC machine tools has led to some changes in the structure of machine tool castings and brought about some problems in casting technology. Based on the analysis of the causes of the defects and locations of the main castings of machine tools, a reasonable structure is designed as far as possible to avoid them.