- Application of Heat Treatment Gear Castings

- Practical significance of pump casting to pump

- What is the equipment for the basic process of stainless steel precision casting?

- How to avoid pollution in stainless steel castings

- How to cool the investment casting quickly?

- Precision forging process of stainless steel

- Matters needing attention in detail handling of stainless Steel Castings

- Advantages of high manganese steel castings

- Heat treatment method of cast Iron platform Ductile iron

- Stainless steel precision forged process measures below

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Gravity casting Technology of Aluminum Alloy

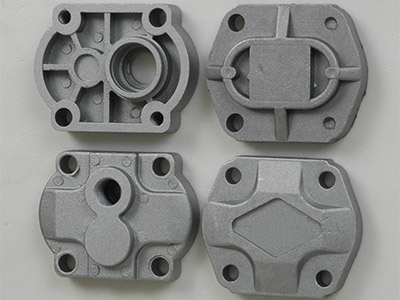

Aluminum alloy casting mold refers to the gravity casting process in which the molten metal is poured into the mold under the action of the earth gravity, also known as gravity casting. Generalized gravity casting includes sand casting, metal casting, investment casting, lost foam casting, clay casting and so on. Gravity casting in the narrow sense mainly refers to metal mold casting, so there are obviously more kinds of gravity casting in the broad sense.

Aluminum alloy casting die-casting die refers to the die that casts metal parts on a special die-casting die-forging machine and completes the die-casting process. The basic process of die casting is as follows: the molten metal is cast at low or high speed and filled into the cavity of the mold, which has a movable cavity surface. With the cooling process of molten metal, pressing and forging, aluminum alloy casting not only eliminates the shrinkage and porosity defects of the billet, but also makes the internal structure of the billet break particles in the forging state. The induction mechanical properties of the billet are improved obviously.

Aluminum alloy casting low pressure casting mold low pressure casting refers to the casting method in which the mold is generally organized above the sealed crucible and compressed air is injected into the crucible to form low pressure on the surface of the molten metal, and the molten metal rises from the riser to fill the mold and control the agglomeration. Aluminum alloy casting this casting method has the advantages of good feeding performance, fine casting structure, simple casting of large disordered thin-walled castings, no riser, metal yield as high as 95%, and easy to complete automation. But the equipment cost is high and the output power is low. General aluminum alloy casting is used for casting non-ferrous alloys. Also known as external low pressure casting.

Aluminum alloy casting is widely used in automobile industry, internal combustion engine production, motorcycle manufacturing, motor manufacturing, gasoline pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, architectural decoration and other industries. Aluminum alloy casting can be made into auto parts, automobile engine accessories, engine cylinders, gasoline engine cylinder heads, valve rocker arms, valve brackets, power accessories, motor end covers, casting housings, pump shells, building accessories, decorative accessories, guardrail accessories, aluminum wheels and so on.