- Practical significance of pump casting to pump

- What are the processing steps of stainless steel precision casting?

- What is the complicated forging process of small precision castings?

- Gravity casting Technology of Aluminum Alloy

- Stainless steel precision forged process measures below

- What are the requirements for the selection of rough stainless steel precision casting?

- Introduction of cast Iron Materials

- What are the common stainless steel precision castings?

- Quality control of gray cast iron

- Basic procedures for stainless steel precision casting

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

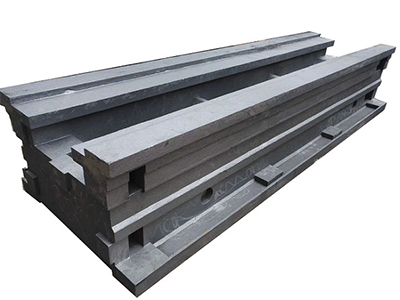

Requirements for moulds of steel castings foundry manufacturers

What are the requirements of steel castings foundry manufacturers for casting mold control? In the process of die casting, there are two different concepts of die casting speed, namely injection speed and mold filling speed. The injection speed refers to the linear speed of the injection punch driven by the pressure oil in the injection cylinder of the die casting machine, and the mold filling speed refers to the linear speed at which the liquid metal enters the mold cavity through the gate under pressure.

The main function of mold filling speed is to quickly feed liquid metal into the cavity before solidification. This is an important factor to obtain castings with clear outline and high surface quality. Speed and pressure are two closely related process parameters. Therefore, in addition to the appropriate injection pressure, the speed of the low pressure mold should be selected correctly.

The filling rate is determined according to the characteristics of the alloy and the structural characteristics of the castings. When the mold filling speed is low, the outline of the casting is not clear, or even can not be formed. When the mold filling speed is higher, the castings with higher surface quality can be obtained even if the injection pressure is lower. However, too high mold filling speed will cause many technical defects and unfavorable die-casting conditions, so steel castings foundry manufacturers need to pay special attention.