- Prevention of stomata in Precision Steel Castings

- Temperature control of stainless steel precision casting

- The difference between Aluminum Alloy forging and Die casting

- The commonly used classification precision castings

- Heat treatment method of cast Iron platform Ductile iron

- Cast wheel hub and forged wheel hub

- What should be paid attention to when casting machine parts

- What are the process measures to change stainless steel precision casting?

- Defects of Sand Mold casting

- Precision casting Machining is often avoided in defects

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

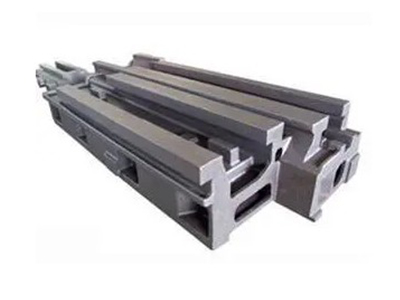

How to make the appearance of large cast steel parts better

Steel casting manufacturers often encounter the appearance of castings when producing large castings, and so on. Why is this? What can manufacturers do to improve their finish, or even better? Manufacturers have summed up what affects the appearance of large castings and how to avoid it based on their years of casting experience.

First is the raw material of castings, such as using the grain size is coarse sand and sand core and compactness is not high also, sand ratio is not appropriate, and using the paint is not suitable for (such as uneven thickness, coating the peeling) such as these will affect the appearance bright and clean degree of large castings, so need to notice where these foundation and avoidance.

The second is the imbalance of chemical composition ratio of large steel casting material, such as low manganese, easy to lead to loose casting and coarse surface material. Therefore, manufacturers need strict testing to avoid this phenomenon released.

In addition, the unreasonable design of the gating system also leads to the phenomenon of loose castings and less than castings, or even incomplete castings.

There is also this is that the steel slag is not treated clean or cast without blocking the slag, so that it runs into the cavity leading to the casting trachoma.

Finally, because of artificial causes, the sand is not cleaned into the sand when closing the box, so that it produces sand holes.

There are other influences on the appearance of the casting finish, which requires the steel casting manufacturers to find in the production can be avoided in time, so that the quality and appearance of the production of large steel casting is better.