- Factors that cause precision casting size defects

- Casting defect examination

- The role of Heat Resistance in Steel Castings

- How to control the temperature of stainless steel precision casting?

- What should I pay attention to in the production process of stainless steel casting?

- What are the problems in the stainless steel precision casting project?

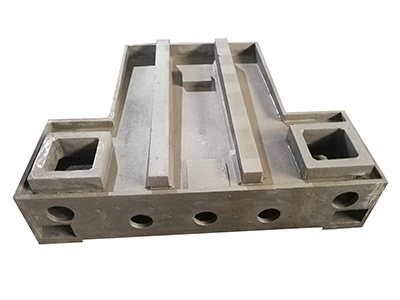

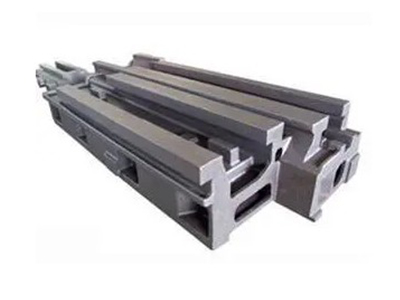

- Sand casting production for large Steel Castings

- Processing process of stainless steel precision casting

- Application of Heat Treatment Gear Castings

- What are the general technical requirements for casting components?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Cast wheel hub and forged wheel hub

The wheels on the market are generally divided into casting and forging, but most people can not tell the specific difference between forging and casting. In fact, due to the different production and processing methods of castings and forgings, their characteristics are also completely different.

1. In the aspect of shape transformation of objects:

Casting is the process of liquefying solid metal and then putting amorphous liquid metal into the mold to obtain things of different shapes (solid-liquid-solid).

Forging is the transformation of an entity of one shape into another. That is, solids change from one shape to another (solid-solid) at high temperature.

2. Focus:

Casting is the process of casting molten metal into a model to obtain castings. The foundry major focuses on the process control of metal smelting process and casting process.

Forging is solid plastic forming, which can be divided into hot working and cold working. Such as extrusion, deep drawing, pier thickening, punching, etc., all belong to forging.

3. Molding speed:

Casting is an one-time molding, the molten liquid metal fills the cavity and cools, and it is easy to produce air holes in the middle of the parts.

Forging is formed slowly, mainly by extrusion at high temperature. The particles in the part can be refined.

4. Performance differences:

Cast steel is brittle and cannot be heat treated.

Forged steel has finer structure, good toughness and strength, and can be subjected to various heat treatments.

Summary:

Advantages of casting wheel hub: price advantage, higher performance-to-price ratio, short production cycle; disadvantages: low strength, easy to break after severe impact.

Forged wheel hub advantages: light weight, good heat dissipation, high strength, not easy to crush after impact, higher safety, strong plasticity, customizable; disadvantages: higher price, longer production cycle.