- Difficulties of stainless steel precision casting processing

- Effectively improve the quality in the process of cast steel production

- Introduction to the adjustment method of rotary kiln roller steel castings

- How to operate the cooling of stainless Steel Precision Castings

- Gravity casting Technology of Aluminum Alloy

- The smelting technology of stainless steel casting process

- Brief introduction of centrifugal ductile cast iron pipe

- Processing process of stainless steel precision casting

- What is the tempering treatment of stainless steel precision casting?

- Application of Heat Treatment Gear Castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

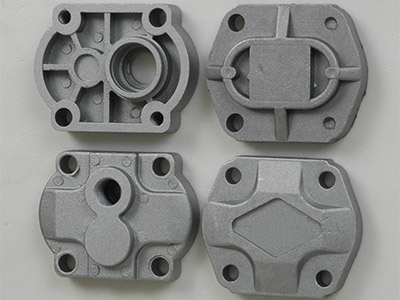

Precision requirements and cost of Precision Castings

The casting precision obtained by different casting methods is different, the initial investment and productivity are also different, and the final economic benefits are also different. Therefore, in order to be more, faster, better and more economical, we should take into account all aspects. The selected casting methods should be preliminarily estimated in order to determine the casting methods with high economic benefits and guarantee the requirements of castings.

In order to fundamentally improve the level of casting technology, we must achieve the following four points:

First, develop simulation technology, improve the accuracy of prediction, strengthen process control, and improve the rate of finished products. The regular problems are not well mastered, thus affecting the rate of finished products in mass production.

Second, the combination of industry, university and research. In addition to the enhancement of innovation consciousness and R & D ability, the independent innovation of enterprises also needs to pay attention to and strengthen the combination of "production, learning and research" with precision casting enterprises as the main body.

Third, attach importance to material research and development. Materials are the foundation of industry, and there is still a lot of work to be done. In the field of aerospace, the research and melting technology of alloy materials, especially superalloys and other new materials need to be improved, and there is still a big gap with foreign countries.

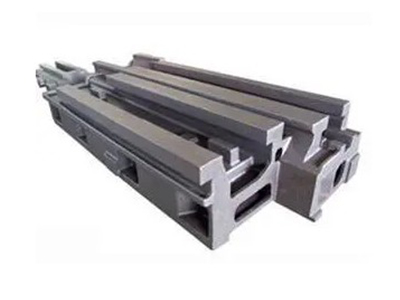

Fourth, pay attention to the improvement of equipment technology. The process is mainly a problem of equipment, and many key equipment, such as some directional solidification equipment, mainly rely on imports, so the research and development of precision casting equipment is still the focus.