- Basic requirements of stainless steel precision casting casting structure

- Precision forging process of stainless steel

- Custom Stainless Steel Casting Manufacturing

- High manganese steel and high chromium cast iron castings

- Application of Heat Treatment Gear Castings

- Learning About a Steel Casting Foundry Where Metals are Cast From

- Application range of high manganese steel castings

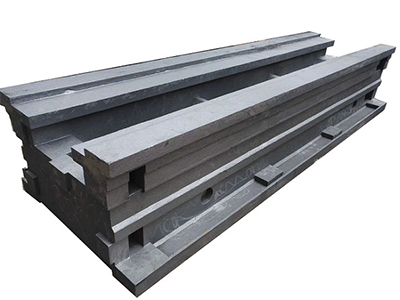

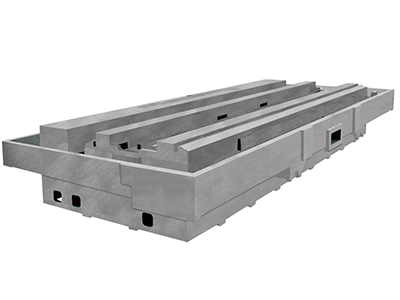

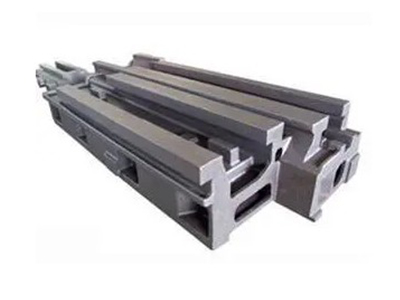

- Factors affecting machine tool castings

- What is the equipment for the basic process of stainless steel precision casting?

- Casting method of Special Agricultural Machinery Castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

The smelting technology of stainless steel casting process

The technical characteristics and precision deviation of stainless steel precision castings are mainly due to the above problems. Now all of us should be clear about stainless steel precision castings. We all need correct methods to operate stainless steel precision castings. What is the melting process of stainless steel casting?

The melting process of stainless steel casting is as follows:

The main contents are as follows: 1. According to the burning loss rate and composition requirements of the elements, the burden is calculated, the addition amount of all kinds of furnace charge is obtained, and the furnace charge is selected.

2. According to the technical requirements of castings, the range of chemical composition of the alloy can be found and the chemical composition can be selected from it.

3. Inspection and preparation of utensils, painting and preheating to prevent pollution of gases, inclusions and harmful elements.

4. Feeding. The general feeding order is as follows: return charge, master alloy and metal material, and metal material with low melting point and easy oxidation, such as magnesium, is added after the furnace charge is melted.

5. In order to reduce the pollution of suction and oxidation of alloy liquid, it should be melted as soon as possible to prevent overheating. According to the need, some alloy liquid should be protected by covering agent.

6. Adjust the temperature and pour. Some alloys should be stirred before pouring to prevent specific gravity segregation.

7. After the furnace charge is melted, the refining treatment is carried out to purify the alloy liquid, and the refining effect is tested.

Stainless steel casting is a casting process with little or no cutting, which is an excellent technology in the foundry industry, and it is widely used. The melting process of stainless steel casting is mainly shared with you above, we need stainless steel casting partners, we should follow the above process to operate.