- What is the equipment for the basic process of stainless steel precision casting?

- Advantages of high manganese steel castings

- Composition ratio of stainless steel cleaning agent

- What is the technological process of stainless steel precision casting?

- Practical significance of pump casting to pump

- Custom Stainless Steel Casting Manufacturing

- What are the common stainless steel precision castings?

- Use sodium silicate sand casting for production

- The role of Heat Resistance in Steel Castings

- The coating and liquidity of stainless steel precision casting coatings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

The difference between precision castings and general castings

Precision castings are different from ordinary castings:

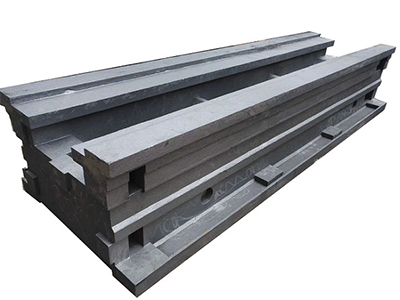

Precision casting is to cast liquid metal water concrete into the same solid model as the casting, which can be formed after cooling. Casting methods include sand casting, special casting, precision casting, V-mold casting. Precision casting in precision casting is classified as special casting. Parts cast by this method do not require production and processing, and may require a very small amount of production and processing to be applied.

General casting belongs to the superficial of forging casting, and aluminum die casting is a casting method of working pressure casting. In the case of compression, the metal material of the liquid is added to the casting solid model at a higher rate. Make it condense under the effect of work pressure. In general, casting materials are subjected to various external forces and deformed in the case of condensation. Precision casting and general casting are two different casting methods, but the regulation of precision casting is higher and the precision is stronger. Compared with the traditional sand casting technology, the castings obtained by precision casting have more specifications and stronger surface smoothness. Including: investment casting, porcelain casting, metal mold casting, working pressure casting, lost foam casting. The overall coating of stainless steel plate precision castings determines the technological performance of the castings, so it is stipulated that the coating quality is high, the silica powder is fine, the viscosity of the coating should not be too high, and the sand removal should be fine. The structural strengthening layer coating can improve the shell and avoid the damage of the shell. Therefore, the coarser silica powder can be used, the viscosity of the coating is high, and the particle size distribution of sand removal is also very large.