- Temperature control of stainless steel precision casting

- Related requirements of Mould for Steel Castings

- Metal Mold casting and Sand casting

- Introduction to the knowledge of stainless steel castings

- What is the technological process of stainless steel precision casting?

- Temperature and Speed of Steel Castings in pouring process

- How to choose suitable cast steel parts

- Steel castings foundry manufacturers introduce the properties of castings

- What is the heat treatment process of precision casting?

- It is recommended that you choose castings like this

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Manufacture and Application of Aluminum Alloy Die Castings

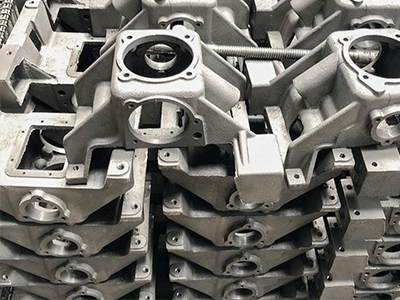

Aluminum alloy die casting, as its name implies, is a kind of parts made by forging liquid aluminum or aluminum alloy under pressure using aluminum raw materials. Aluminum alloy die casting has different names in different places, such as aluminum die casting parts, die casting aluminum parts, die casting aluminum alloy die castings, aluminum alloy die casting parts and so on.

Lu's physical and chemical properties determine that it has good fluidity, so its plasticity is stronger than that of other metal materials. Moreover, the casting process is cast in a pressure die casting machine, so aluminum alloy die castings can make a variety of complex shapes, as well as good precision and smoothness. as a result, the mechanical processing of castings and the casting allowance of metal aluminum or aluminum alloy are greatly reduced, which saves not only electric power, metal materials, but also labor costs.

When aluminum alloy die castings are processed, the application of some external forces will be beneficial to the good shaping of the castings. Let's take a look at the types of die casting according to the pressure methods used in the mold.

1. Pressure casting, there are three casting methods: low pressure (pressure does not exceed 20MPa), medium pressure (pressure does not exceed 300MPa) and high pressure (pressure above 3000MPa).

2. Step-down casting, such as vacuum suction casting, etc.

3. Normal pressure casting is generally used in metal mold casting and sand mold casting.

4. Solidification under pressure, centrifugal casting, high pressure solidification casting (such as liquid die forging) and so on.