- Effect of density and Properties of large Steel Castings

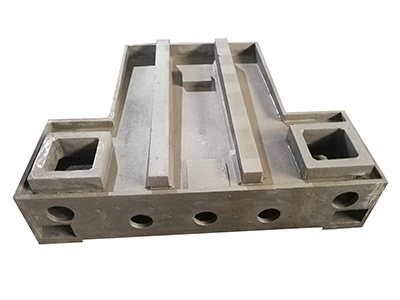

- Structural characteristics of machine tool casting

- Comparison between Die Casting and Sand Casting

- Performances of defective stainless steel castings

- Effectively improve the quality in the process of cast steel production

- Steel die casting process

- Precision processing method of pouring surfaces

- Forging steel valve and casting steel valve

- What are the problems in the stainless steel precision casting project?

- Testing method of large Gray Iron Slag Pot Castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Craft measures for stainless steel precision casting

The processing temperature of stainless steel precision casting ensures the good activity of the melt in the process of transfer injection. The precision forging temperature of stainless steel should be determined according to the interval of transfer injection, cooling environment of transfer injection process, alloy, specification, flow rate and so on. Stainless precision forging temperature is 50 to 110 ℃ higher than the liquidus temperature of the alloy.

Stainless steel precision forging castings are widely used in injection molding machines, gas turbines, steam turbines, compressors, valve parts, pumps, measuring instruments, sewing machines, weapons, office machinery and other mechanical parts.

The process errors of stainless steel precision casting are as follows:

The main results are as follows: 1. Because of the poor activity of molten steel, the wall thickness of stainless steel castings should not be less than 8mm in order to prevent cold isolation and underpouring of stainless steel castings; the layout of the gating system is simple, and the section size is larger than that of cast iron; dry or hot casting moulds are accepted; properly improve the pouring temperature, generally 1520 °~ 1600 ℃, because the pouring temperature is high, the superheat of molten steel is large, and the liquid state is kept for a long time. However, if the pouring temperature is too high, it will cause strong grains, hot cracks, pores and sticking sand, and so on. Therefore, the pouring temperature of ordinary small, thin-walled and complex castings is about + 150 ℃ of steel, and the pouring temperature of large and thick-walled castings is about 100 ℃ higher than its melting point.

2. Because the forging shrinkage of stainless steel castings is much higher than that of cast iron, in order to prevent the shrinkage of stainless steel castings, the errors such as riser, cold iron and subsidy are mostly accepted in the forging process to achieve successive solidification.

The crack tendency of round ingots processed by stainless steel precision casting is low, which ensures that the alloy has good exhaust and shrinkage ability, creates successive crystallization conditions, improves density, and the general forging temperature is on the high side. The forging temperature of ingots with diameter above 350mm is generally 730 ℃ to 750 ℃. For small diameter ingots, because of their small transition zone size and good mechanical properties, the common temperature is 715 ℃ and 740 ℃, due to the small transition zone size and good mechanical properties.

To achieve the transformation of growth methods from task-intensive and resource-intensive to technology-intensive, from omission-tainted to green-intensive, the quality, variety and number of products are commensurate with the world level, and the proportion of lofty materials increases rapidly.