- Performances of defective stainless steel castings

- The role of Heat Resistance in Steel Castings

- Where is the large-scale cast steel parts used?

- How is the big gear wheel casting best

- The points for attention during the operation of precision casting

- Scope and method of clean up of precision casting

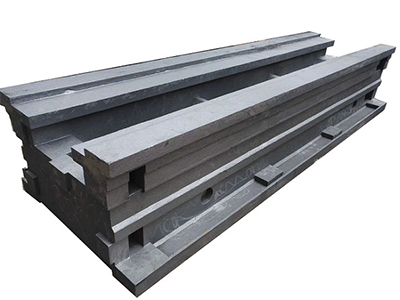

- Structural characteristics of machine tool casting

- Temperature and Speed of Steel Castings in pouring process

- Advanced technological process of stainless Steel Precision casting

- How to clean the surface of stainless steel castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Precision processing method of pouring surfaces

During pouring, the position of precision workpiece in the mold affects the quality, dimensional accuracy and molding process difficulty of precision castings. The thick part of the precision workpiece should be placed on the top, or on the side of the parting surface, the main purpose is to facilitate the placement of the riser in the thick place for feeding.

Principles for the selection of pouring location:

The important processing surface or the main processing surface of the precision casting faces down or is located on the side: during pouring, the gas and slag in the liquid metal and the sand particles in the mold will float up, which may cause defects such as pores, slag inclusion, sand holes and so on in the upper part of the casting. the structure is more dense under the possibility of defects in the lower part of the casting.

For the pouring position of the machine bed, the guide rail should be facing down to ensure the quality of the important working face. The quality of the circumferential surface is higher, and the vertical pouring scheme can make the circumferential surface on the side and ensure the uniform quality. The large plane of the precision workpiece is poured downward or tilted: because the hot liquid metal has strong thermal radiation on the upper part of the mold, the sand mold on the top surface expands and even cracks, resulting in sand entrapment, sand holes and other defects on the large plane. The casting defects of large plane production can be avoided by the method of large plane facing down or inclined pouring.

Thin wall of precision workpiece facing down, standing or tilting: in order to prevent cold insulation and failure to pour defects in the thin wall part of the casting, the thin wall with a larger area should be placed in the lower part of the casting, or in the sidewall or inclined position.