- Manufacturers generally choose which cast steel process

- Steel die casting process

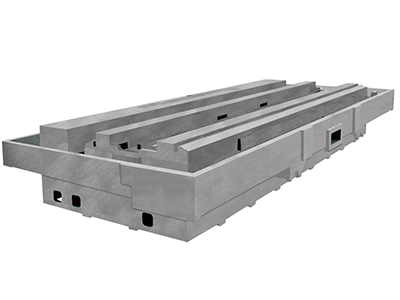

- Structural characteristics of machine tool casting

- The reason for the high carbon content of stainless steel castings

- How to operate the cooling of stainless Steel Precision Castings

- Basic requirements of stainless steel precision casting casting structure

- Process Classification of Precision casting

- Key factors of Gear Machining by stainless Steel Precision casting

- How to control the temperature of stainless steel precision casting?

- Stainless steel precision casting is suitable for high temperature processing castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

How to control the temperature of stainless steel precision casting?

In the process of stainless steel precision casting, the solidified materials such as liquid at room temperature are directly poured into the mold of its specific shape, most of which are solid and then directly heated into liquid metal. the metal materials used are lead, copper, iron, aluminum and so on. So do you know how to control the temperature of stainless steel precision casting?

The main results are as follows: 1. the temperature of the melting furnace is unstable, so the temperature difference will occur in the casting process, which has a great impact on the accuracy of the measurement. The temperature control in strict casting is to use these temperature data to find a temperature range that can determine the quality of castings.

2. If the non-standard melting technology is used in casting, it will also have a corresponding impact on the temperature measurement. Such as excessive boiling of elements with high steam pressure, disturbance on the surface of the molten pool or the formation of reaction products.

3. The signal processing ability of the measuring equipment itself is not strong, because each analog between the measuring instrument and the control equipment will cause errors.

Stainless steel precision casting mold material can be metal, sand or ceramic, in the process of use according to its different requirements, the use of different methods, such a production method is called casting, the metal mold can be gray iron or ductile iron and so on.

Stainless steel precision casting temperature is an important factor to determine the quality of stainless steel precision castings, such as mold temperature, cycle time and the methods of operators all need accurate temperature measurement results to guide.