- The main points of quality control of ductile iron casting

- Brief introduction of centrifugal ductile cast iron pipe

- Effectively improve the quality in the process of cast steel production

- How to operate the cooling of stainless Steel Precision Castings

- Temperature control of stainless steel precision casting

- How to cool the investment casting quickly?

- Precision processing method of pouring surfaces

- The reason for the high carbon content of stainless steel castings

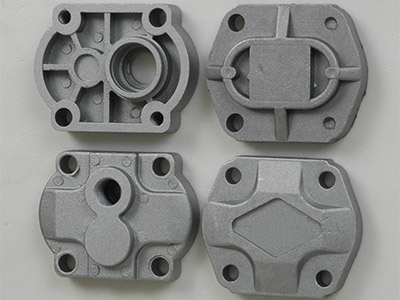

- Stainless steel precision casting is a casting process with little or no cutting

- Heat treatment method of cast Iron platform Ductile iron

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

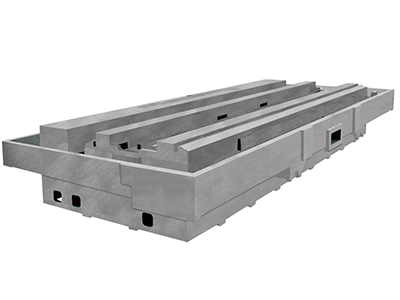

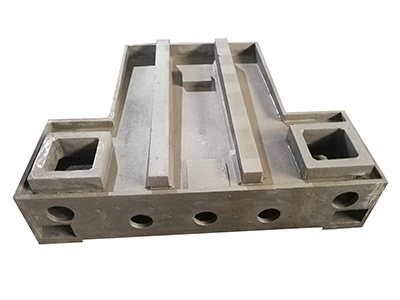

Prevention measures to avoid defects in machine tool castings

1. There are holes of different sizes in the interior, surface or near the surface of machine tool castings, some are round, long and irregular, some are single, and some are gathered into pieces. The color is white or dark, and sometimes it is covered with an oxide scale. The preventive measure to avoid is to reduce the suction capacity of metal during smelting. In order to reduce the outgassing of sand mold in the pouring process and improve the structure of machine tool castings, it is necessary to improve the air permeability of sand mold and core so that the gas in the mold can be discharged smoothly.

2. the shrinkage hole is irregular in shape, rough in the hole and coarse grain in the interior of the thick section of the machine tool casting, the interior of the two interfaces and the interior or surface of the intersection of the thick section and the thin section. The machine tool castings with small and uniform wall thickness should be solidified at the same time, while the machine tool castings with large and uneven wall thickness should be solidified sequentially from thin to thick, and the cold iron with reasonable riser should be placed.

3. The small and discontinuous shrinkage holes in the machine tool castings gather in one or more places, the grains are coarse, there are very small holes between the grains, and water permeates during the hydraulic test. At the joint between the walls, the hot joints are minimized, and the pouring temperature and speed are reduced as much as possible.

4. the slag hole is an irregularly shaped hole in the interior or surface of the machine tool casting. The hole is not smooth and is completely or partially filled with slag. Increase the temperature of molten iron. Reduce the viscosity of molten slag. Improve the slag blocking ability of the gating system. Increase the inner fillet of machine tool castings.

5. Sand holes have holes filled with molding sand inside or on the surface of machine tool castings. Strictly control the molding sand performance and molding operation, and pay attention to cleaning the mold cavity before closing the mold.

6. Hot crack there are penetrating or non-penetrating cracks on the machine tool castings (note if curved), and the metal skin is oxidized at the crack. The content of S and P in molten iron is strictly controlled. The wall thickness of machine tool castings is as uniform as possible. Improve the concession of molding sand and core. The sprue and riser should not hinder the shrinkage of machine tool castings. Avoid sudden changes in wall thickness. You can't drive too early. Do not chill machine tool castings.

7. There are penetrating or non-penetrating cracks on the machine tool castings (mainly straight), and the metal epidermis is oxidized at the cracking.

8. The lack of meat in the machine tool castings caused by the liquid metal not filling the mold cavity can not be irrigated. Increase pouring temperature and pouring speed. Don't cut off the current and prevent fire running.

9. Sandwiched on the surface of machine tool castings, there is a layer of metal nodule or sheet, and a layer of molding sand is sandwiched between the metal tumor sheet and the machine tool casting. Strictly control the properties of molding sand and core sand. The gating system makes the liquid metal flow smoothly.Large plane machine tool castings should be inclined and poured.

9. Sandwiched on the surface of machine tool castings, there is a layer of metal nodule or sheet, and a layer of molding sand is sandwiched between the metal tumor sheet and the machine tool casting. Strictly control the properties of molding sand and core sand. The gating system makes the liquid metal flow smoothly.Large plane machine tool castings should be inclined and poured.

10. There is an unfused gap or pit in the machine tool casting, and the edge of the boundary is smooth. Increase pouring temperature and pouring speed. gating system. The flow does not stop during pouring.