- How to make the appearance of large cast steel parts better

- The difference between Ductile Iron Castings and Gray Iron Castings

- There are several main types of cracks in castings

- Craft measures for stainless steel precision casting

- Introduction to the adjustment method of rotary kiln roller steel castings

- The reason for the high carbon content of stainless steel castings

- How to control the temperature of stainless steel precision casting?

- Steel die casting process

- Testing method of large Gray Iron Slag Pot Castings

- What needs to be done before delivery of large steel castings?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

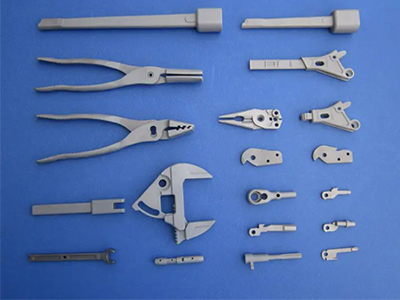

Scope and method of clean up of precision casting

The process of removing precision castings from the mold, removing the excess parts outside the body, and polishing the inner and outer surfaces of the castings. Core removal and surface cleaning can be divided into two types: dry and wet. Dry cleaning is the use of mechanical equipment to clean castings. The equipment used is simple, the production efficiency is high, it has great adaptability to different types of castings, and it can remove the core and clean the surface effectively. The disadvantage is that the equipment is often dusty, noisy and pollute the environment. Wet cleaning has no dust, but due to the use of water as the medium, the surface of the casting is easy to rust. A large amount of sewage and water-carrying sediment are produced in the process of operation, which brings problems such as sand and water regeneration and sludge treatment.

1. Roller cleaning. The casting and star iron are loaded into a circular drum together. When the drum rotates, the sand inside and outside of the casting is removed by mutual impact and friction among the casting, star iron and waste sand, and the casting surface is polished. At the same time, the flying edge burr can also be partially removed.

This kind of equipment is suitable for cleaning small and medium-sized castings with simple shape and thick wall.

2. Shot blasting cleaning. The impact force of high-speed moving steel shot, iron shot and abrasive flow is used to remove the core and stick sand, and grind the casting surface. In addition, the commonly used shot blasting cleaning equipment are shot blasting cleaning table and shot blasting cleaning room and so on. The shot blasting cleaning machines used for continuous production include chain plate shot blasting drum, continuous shot blasting cleaning table, suspended continuous production shot blasting cleaning room and so on. The cost of operation and maintenance of this kind of equipment is high.

3. Hydraulic sand cleaning. The high-pressure water is shot from the nozzle to the treated castings through the pipeline, and the sticky sand of the core and castings is removed by the kinetic energy and scouring action of the water flow. Hydraulic sand cleaning is usually equipped with an open cleaning room composed of section steel and steel plate, the bottom is provided with a rotary table, and the spray gun is installed on the side wall, which can move up and down and rotate, so that the high-pressure water can be shot to any part except the bottom of the casting. Sometimes in order to improve the efficiency of removing sticky sand from the surface of precision castings, abrasives such as quartz sand are introduced into the appropriate position of the spray gun to obtain high-speed water-sand flow. This method is generally called water sand cleaning.

4. Sand cleaning by water explosion. After the mold is poured, the casting is poured into the box when it is cooled to the specified temperature, and immediately immersed in the pool. The water seeps into the mold through all the cracks and vaporizes rapidly in contact with the high temperature metal. The shock wave can basically remove the sand attached inside and outside the casting. The water blasting sand cleaning method has the advantages of short working time and high efficiency, so it has been widely used in steel casting workshops. It is generally used to deal with steel castings with a carbon content of less than 0.35%.