- Selection of stainless steel precision casting cold iron materials

- What is the complicated forging process of small precision castings?

- There are several main types of cracks in castings

- Heat treatment method of cast Iron platform Ductile iron

- Stainless steel precision casting is suitable for high temperature processing castings

- Why is it said that deoxidation is the key to improve the quality of molten steel?

- What are the models of ductile iron castings?

- Basic procedures for stainless steel precision casting

- How to make the appearance of large cast steel parts better

- Advanced technological process of stainless Steel Precision casting

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

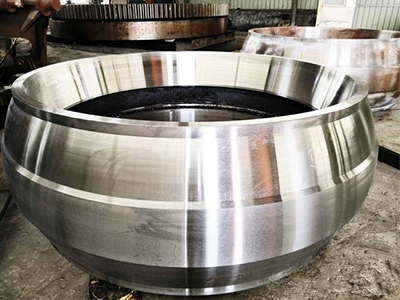

What needs to be done before delivery of large steel castings?

After the manufacturer has cast or processed large steel castings, what should be done before delivery? The last item before delivery is testing, only qualified products are allowed to leave the factory, for unqualified products, are rejected.

Testing of castings is not how you want to test, cast castings can not be tested immediately, but can be tested 1-2 days after casting. That is because defects in castings after casting will be delayed, such as cracks, etc., and because of the large volume and weight of castings, manufacturers use non-destructive testing, such as DC or half-wave rectifiers, portable magnetic particle flaw detection machines, to detect local large steel castings, and because of the large volume, manufacturers will choose two mutually perpendicular testing, so the detection is relatively accurate. It should be noted that the testing of large castings is carried out in accordance with the second layer testing standard by default.

Manufacturers will also choose according to the actual situation of castings and now ultrasonic testing, the use of sound waves can detect whether there are defects in castings, this detection sensitivity is high, can detect smaller defects in castings.

For the inspection of defects in semi-finished products or finished products of castings, X-ray inspection can be selected, which is highly penetrating and convenient for manufacturers to find their defects in time.

Finally, liquid penetrant can be selected to detect the accuracy and quality of the surface of large steel castings, but the disadvantage is that the operation is complex.