- Basic requirements of stainless steel precision casting casting structure

- Related requirements of Mould for Steel Castings

- Effectively improve the quality in the process of cast steel production

- Factors affecting the accuracy of Castings

- How to cool the investment casting quickly?

- The characteristics of precision casting

- The coating and liquidity of stainless steel precision casting coatings

- The difference between Ductile Iron Castings and Gray Iron Castings

- Stainless steel precision casting is a casting process with little or no cutting

- Causes of insufficient precision specifications of precision castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

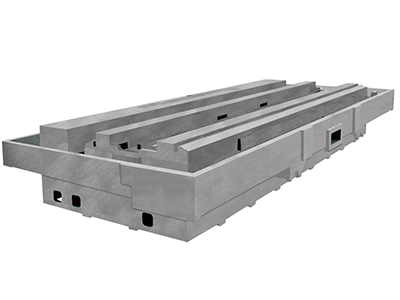

Steel casting production standard requirements

Standard requirements for steel casting production.

1. The composition of hot metal used in manufacturing should meet the requirements of customers and design drawings.

2. When pouring, the amount of iron should be enough and the shrinkage should be good.

3. Accurately calculate the solidification shrinkage of hot metal and control the dimensional accuracy of the finished product.

4. When there are shrinkage holes and pits on the upper and lower end faces and inner surfaces that are difficult to eliminate, which are larger than 40mm, the equipment Engineering Department, the Technical Department and the steelmaking plant (or user unit) shall be notified for acceptance treatment, and hot metal leveling is not allowed directly.

5. The cap mouth, ingot mold body, chassis, plate assembled contact surface and the bottom surface of the central injection pipe should be machined. The requirements are smooth and smooth, seam gap cluster ≤ 2mm. The stop shall be in good condition and the centerline should be straight.

6. Casting blanks should be treated by natural or artificial aging before machining.

Natural and artificial aging reference time for different types of ingot moulds.

The reference dimensions and thickness of the central injection pipe, chassis, base, thermal insulation and artificial aging are specified.

The reference annealing system of artificial aging is as follows: heating up ≤ 80 ℃ / h, heat preservation at 700 ±20 ℃, cooling at ≤ 50 ℃ / h, furnace at ≤ 100 ℃.