- Composition ratio of stainless steel cleaning agent

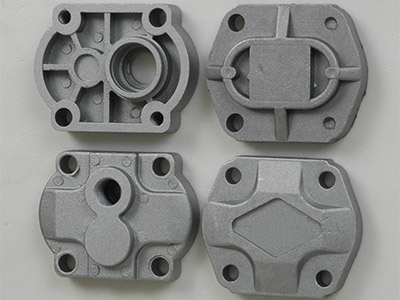

- What are the determination methods of stainless steel precision casting?

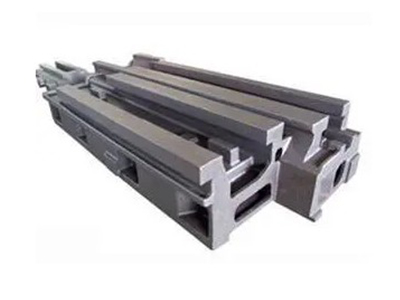

- Prevention measures to avoid defects in machine tool castings

- Selection factors of stainless Steel Precision casting methods and its finished products

- What are the common stainless steel precision castings?

- Application range of high manganese steel castings

- Characteristics and calculation of gating system for Steel Castings

- Basic characteristics of Gray Iron Castings

- About machine tool casting understanding

- Manufacture and Application of Aluminum Alloy Die Castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

How to cool the investment casting quickly?

When in the grinding ball manufacturing, according to the increase of chromium content, on the one hand, the total number of carbides can be increased, on the other hand, chromium-containing carbides can be produced, so that the strength of the grinding ball can be significantly improved; in addition, the increase in the content of copper in the composition makes the conventional fine grains strengthen and optimize the crystal, so the impact value is significantly improved. In addition, the addition of Ca and other elements with solubility close to zero in the carbide is added to the mildew agent, and the biological enrichment in the Z front of the carbide hinders the growth and development of the carbide. The addition of Re elemental absorption order in the carbide surface also prevents the growth of the carbide. In addition, the addition of M05V as the carbide crystal is the key to optimize the crystal and make the grinding ball made of aluminum die casting in lost foam without quenching and tempering treatment HRC.

1. The selection of chilling molding design raw materials can accelerate the cooling rate of vanishing castings.

Due to the vacuum pump lost foam aluminum die casting old sand reuse rate of about 98%, although the selection of special sand one-time project investment expansion, but the economic benefits of casting quality improvement can not be ignored. The cooling rate of chilled sand and quartz sand can be increased by 1-4 times which is significantly higher than that of traditional sand casting. the actual cooling effects are as follows: high purity graphite sand steel ball chromite sand and zircon sand.

2. According to the adjustment of casting composition and lifting modification, the bad harm caused by slow cooling and condensation can be offset.