- Where is the large-scale cast steel parts used?

- Related requirements of Mould for Steel Castings

- Basic procedures for stainless steel precision casting

- The role of Heat Resistance in Steel Castings

- The difference between precision castings and general castings

- Inspection Standard and testing content of Steel Castings

- How to make the appearance of large cast steel parts better

- The difference between Ductile Iron Castings and Gray Iron Castings

- Which kind of steel castings is the most suitable for non-destructive testing

- Characteristics and calculation of gating system for Steel Castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

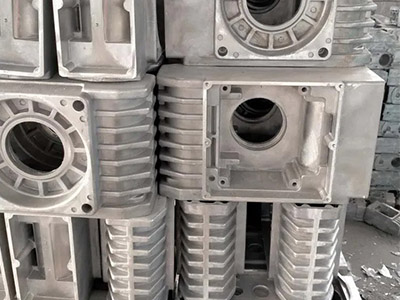

Metal Mold casting and Sand casting

Sand casting, as the name implies, is to take the sand mold as the basic mold, pouring metal solution to form the required castings. Its advantages are: low material price, easy to obtain, strong adaptability, wide range of use, and can correspond to a variety of production needs, including single casting and batch casting.

Metal mold casting, also known as hard mold casting. Unlike sand casting, it uses metal moulds that can be reused hundreds or thousands of times. However, it has some limitations, such as casting weight, shape and thickness requirements.

First, advantages:

The main results are as follows:

(1) the mechanical properties of metal mold castings are higher than that of sand mold castings. For the same alloy, the tensile strength can be increased by 25%, the yield strength can be increased by about 20%, and the corrosion resistance and hardness can also be significantly improved.

(1) the mechanical properties of metal mold castings are higher than that of sand mold castings. For the same alloy, the tensile strength can be increased by 25%, the yield strength can be increased by about 20%, and the corrosion resistance and hardness can also be significantly improved.

(2) the precision and surface finish of castings are higher than those of sand castings, and the quality and dimension are stable.

(3) the finished product rate of castings is high, and the consumption of liquid metal can be reduced by 15-30%.

(4) 80-100% molding materials can be saved by not using sand or less sand; in addition, the production efficiency of metal mold casting is high; the causes of casting defects are reduced; the process is simple and easy to realize mechanization and automation.

Second, shortcomings:

(1) the manufacturing cost of metal mould is high.

(2) the metal mold is airtight and non-concession, which is easy to cause defects such as inadequate washing, cracking or daylight of castings.

(3) in metal mold casting, the working temperature of the mold, the pouring temperature and speed of the alloy, the residence time of the casting in the mold and the coating used are very sensitive to the quality of the casting, which needs to be strictly controlled.

See here, the advantages and disadvantages between the two are also very obvious. Sand casting is a more cost-effective choice, while metal mold casting is suitable for products that require higher quality and higher production efficiency. Kunfeng heavy Industry can use wood mold sand casting or metal mold casting to meet your personalized casting needs.