- Selection of stainless steel precision casting cold iron materials

- Pore diameter and wall thickness of precision casting processing

- How are Stainless Steel Castings Made?

- What are the common stainless steel precision castings?

- The role of Heat Resistance in Steel Castings

- What is the equipment for the basic process of stainless steel precision casting?

- The difference between Aluminum Alloy forging and Die casting

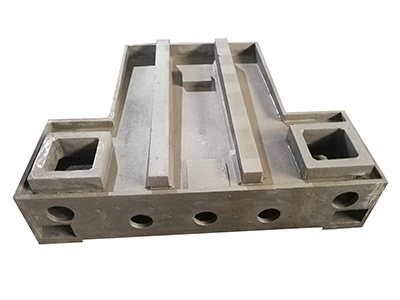

- Prevention measures to avoid defects in machine tool castings

- Application range of high manganese steel castings

- What are the processing steps of stainless steel precision casting?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Manufacturers generally choose which cast steel process

Sometimes customer service received a customer's consultation "you produce steel casting with what process?" At this time some small partners have questions about what process, what does it mean? This process is a casting process. The casting process is to melt the metal and pour it into the mold to cast a variety of steel castings.

Many founders use the most casting process, the most used is the mold, some molds will be destroyed in the casting process, can not be recycled, another kind of mold opening in casting can be reused, compared with manufacturers and the general situation of the use of more.

Many large steel casting manufacturers mainly use sand casting process, in which the mold is wood mold, which can be used repeatedly and recycled, suitable for large-scale steel casting, strong production flexibility, relatively light use. Generally, the weight of castings produced by large casting factories is 1 ton, and the steel used is general carbon steel or low alloy steel castings. Some manufacturers can produce small castings, specifically with the strength and scale of the manufacturer; In sand casting, the shape of the wood mold is the same as that of the casting. When the liquid steel solidifies, the sand mold will be removed by the manufacturer. The wood mold and sand can be reused, so the sand casting has high cost performance.

There are also rapid molding, centrifugal casting and extrusion of semi-solid metal billets into molds or dies, which are generally suitable for small steel castings and can be mass-produced.