- Cast wheel hub and forged wheel hub

- Prevention of stomata in Precision Steel Castings

- Custom Stainless Steel Casting Manufacturing

- Precision forging process of stainless steel

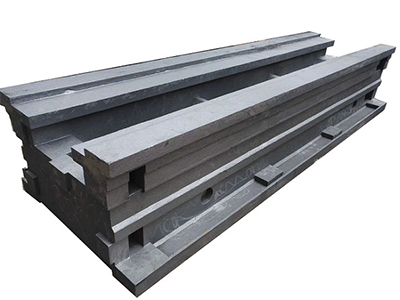

- Causes of the formation of two stress of machine tool casting

- Basic characteristics of Gray Iron Castings

- Factors that cause precision casting size defects

- What should be avoided during the casting process of precision casting manufacturers?

- Inspection Standard and testing content of Steel Castings

- The coating and liquidity of stainless steel precision casting coatings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

What are the processing steps of stainless steel precision casting?

Stainless steel precision casting is a casting process with little or no cutting, and it is an excellent technology in the casting industry. it is widely used, not only for various types and alloys. So do you know what the processing steps of stainless steel precision casting are?

The processing steps of stainless steel precision casting are as follows:

1. Heating and preplasticizing: driven by the transmission system, the screw conveys and compacts the material in the hopper. Under the mixed action of the shear and friction of the external heater, screw and barrel, the material gradually melts, and the corresponding amount of molten plastic accumulates in the head of the barrel.

2. Clamping and locking: the clamping mechanism pushes the template and the movable mold parts installed on the movable template close the locking mold to ensure that sufficient clamping force can be provided to lock the stainless steel precision casting mold.

3. Move the injection device forward: after the mold is closed, push the whole injection seat forward to make the injection machine nozzle fit with the mold main gate.

4. Injection pressure keeping: the mold is locked, and after the manufacturer operates the nozzle to fit the mold, the injection cylinder enters the high pressure oil, pushes the screw forward relative to the barrel, and injects the melt accumulated at the head of the barrel into the mold cavity with sufficient pressure, due to the decrease of temperature. Plastic volume shrinks.

5. Pressure relief: when the melt at the mold gate freezes, the pressure can be released.

6. Withdrawal of the injection device: generally speaking, after the pressure relief is completed, the screw can rotate and retreat to complete the next feeding and preplasticizing process.

Stainless steel precision casting is a casting process with little or no cutting, and it is an excellent technology in the foundry industry.