- Common casting methods of Aluminum and Aluminum Alloy

- Factors affecting machine tool castings

- Gray iron casting production supplier

- Performances of defective stainless steel castings

- Forging steel valve and casting steel valve

- Where is the large-scale cast steel parts used?

- Metal Mold casting and Sand casting

- How to repair the defects of precision casting

- Stainless steel casting manufacturing process

- Calculation method and proportion of casting riser design

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

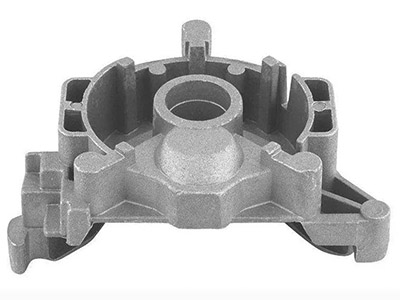

Inspection Standard and testing content of Steel Castings

Cast steel is a method of pouring molten metal into a mold and then cooling it to make it the desired shape. The casting is followed by the final finishing step to obtain the required surface finish to remove the excess metal remaining in the casting process. The advantage of this approach is that the component design is very flexible and can easily adapt to many different shapes. The workpiece produced by cast steel is cast steel, which is a kind of alloy. Cast steel can be divided into three categories: cast low alloy steel, cast carbon steel and cast special steel.

Inspection range of steel castings:

Steel castings, mine steel castings, metallurgical steel castings, water conservancy steel castings, automobile steel castings, valve steel castings, marine steel castings, precision steel castings, film-coated sand steel castings, alloy steel castings, screw steel castings, etc.

Inspection items of steel castings:

Penetration testing, magnetic particle testing, mechanical properties testing, non-destructive testing, ultrasonic testing, flaw detection, chemical composition testing, metallographic testing, hardness testing, inclusion testing, internal porosity testing, surface quality testing, defect testing, mechanical properties testing, crack testing, porosity testing, physical tensile testing, residual stress testing, etc.