- Heat treatment method of cast Iron platform Ductile iron

- What are the processing steps of stainless steel precision casting?

- The Investment casting method can save time

- What are the surface cleaning methods of stainless steel precision casting?

- Basic procedures for stainless steel precision casting

- Precision cast stainless steel thermal treatment technology

- It is recommended that you choose castings like this

- Measurement of the size of large -scale casting steel parts

- What is the equipment for the basic process of stainless steel precision casting?

- Application fields and products of iron castings

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

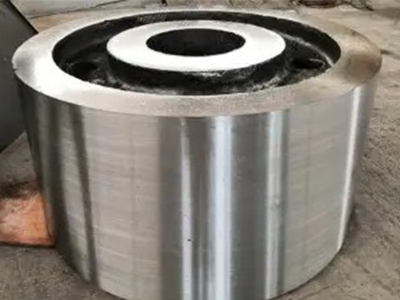

Influence of factors on the appearance of Roller Steel Castings

When casting steel products, steel casting enterprises should pay attention not only to the quality of large steel castings, but also to the overall appearance of the products. For example, Kunfeng casting in the production of roller steel castings, will pay special attention to the following problems, to avoid the appearance of roller steel castings affected by these factors:

1. The grain size of molding sand and sand core of roller steel castings, if too thick, will directly affect its compactness; if there are many attachments, the fire resistance will be low and the thermal conductivity will be poor; when there is more recycled sand, the sintering temperature will also be low.

2. If the liquid pouring temperature of the roller steel casting is too high, the hydraulic pressure will be relatively high, for example, if the upper box or gate cup is high, the static pressure of the liquid will also be too high. The fluidity of the liquid is good, and the surface tension is low, so special attention should be paid to pouring. If the gating system or riser is not handled properly, it is easy to cause local overheating.

3. The quality of the coating used in roller steel castings should also be selected. if the selection is not good and the coating is not uniform enough, the coating is easy to peel off.

Different steel castings will be used with a variety of different mechanical equipment, and relative customers will have different requirements for the quality of steel castings produced by Great Wall steel castings. for example, the shape, performance and structure are all directly related to the steel castings themselves. In the process of steel casting production, a little carelessness can easily lead to cracks, sand sticking, sand washing and other defects in the casting process, which will lead to the decline of the appearance quality of roller steel castings, which increases the finishing workload. the appearance of the products of other steel casting manufacturers will be very different.