- How to prevent machine tool casting defects

- Key factors of Gear Machining by stainless Steel Precision casting

- Heat treatment method of cast Iron platform Ductile iron

- What are the surface cleaning methods of stainless steel precision casting?

- The main points of quality control of ductile iron casting

- Learning About a Steel Casting Foundry Where Metals are Cast From

- The commonly used classification precision castings

- Practical significance of pump casting to pump

- What should be avoided during the casting process of precision casting manufacturers?

- Causes of the formation of two stress of machine tool casting

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

The points for attention during the operation of precision casting

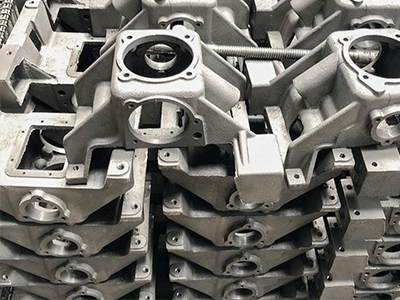

Precision casting manufacturers are using silica sol precision casting technology, processing from wax, injection, dewaxing, roasting, casting the whole process of automatic control. Precision casting is not allowed for insufficient or excessive material composition, which fundamentally ensures the quality and reliability of products.

Due to the poor fluidity of liquid steel, the wall thickness of cast steel should not be less than 8mm in order to prevent cold isolation and insufficient casting. The structure of the gating system is simple and the section size is larger than that of cast iron. Dry casting or hot casting; Appropriate increase the pouring temperature, generally 1520℃ ~ 1600℃, because the pouring temperature is high, the superheat of molten steel is large, the liquid time is long, the fluidity can be improved. However, if the pouring temperature is too high, it will cause defects such as coarse grain size, hot cracking, porosity and sticky sand. Therefore, generally small, thin-walled and complex shape castings, the pouring temperature is about the melting point temperature of steel +150℃; The pouring temperature of large, thick-walled castings is about 100℃ higher than the melting point.

Since the shrinkage of cast steel is much greater than that of cast iron, in order to prevent shrinkage cavity and shrinkage porosity of castings, riser and cooling iron and subsidies are mostly adopted in the casting process to achieve sequential solidification. In addition, in order to prevent shrinkage hole, shrinkage porosity, porosity and crack defects of the cast steel, the wall thickness should be uniform, avoid sharp Angle and right Angle structure, adding sawdust in the mold sand, adding coke in the core, and using hollow core and oil sand core, to improve the sand mold or core's concession and permeability.

The melting point of cast steel is high, and its pouring temperature is also high. The interaction between molten steel and casting material at high temperature is easy to produce sand defect. Therefore, precision casting manufacturers should use artificial quartz sand with high refractoriness as the casting mold, and brush the coating made of quartz powder or zirconium sand powder on the surface of the casting mold.