- Comparison between Die Casting and Sand Casting

- How are Stainless Steel Castings Made?

- Heat treatment method of cast Iron platform Ductile iron

- What is the difference between casting and forging

- The Investment casting method can save time

- Testing method of large Steel Castings in quality Inspection

- The difference between Aluminum Alloy forging and Die casting

- Factors affecting precision casting accuracy

- Measurement of the size of large -scale casting steel parts

- What are the process measures to change stainless steel precision casting?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

What are the requirements for the selection of rough stainless steel precision casting?

There are many casting processes of stainless steel precision casting, such as metal mold casting, dewaxing casting, sand casting, investment casting and so on, among which sand casting and investment casting are commonly used. So do you know what are the requirements for the selection of blank in stainless steel precision casting?

The requirements for blank selection in stainless steel precision casting are introduced as follows:

1. The material and mechanical performance requirements of precision casting parts: the technological properties and mechanical properties of the parts roughly determine the type of blank. For example, the billet of cast iron parts; the bar is commonly used for steel parts with simple shape and low requirements for mechanical properties.

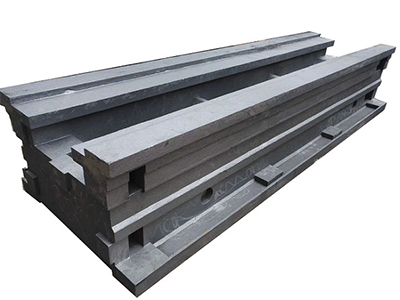

two。. Structural shape and size of parts: the blanks of large and simple parts are mostly cast by sand casting or free forging, the blanks with complex structure are mostly cast, and the blanks of small parts can be molded or pressed. The blank of steel parts is mainly used for forgings.

3. Make full use of new technology and new materials: in order to save materials and energy and improve the efficiency of machining, casting methods and materials such as precision casting, precision forging, cold rolling, cold extrusion, powder metallurgy, profile steel and engineering plastics should be fully considered. In this way, the amount of machining can be greatly reduced, even without the need for processing.

4. Existing production conditions: when determining the billet, it should be combined with specific production conditions, such as the actual level and capacity of on-site production, the possibility of outsourcing, etc., otherwise it will not be realistic.

Stainless steel precision casting is a kind of objects cast by metal, which can be made into various shapes and has a wide range of applications, such as blank of machinery and equipment parts, blank of valve body and so on.