- What is the complicated forging process of small precision castings?

- Stainless steel casting manufacturing process

- Selection factors of stainless Steel Precision casting methods and its finished products

- There are several main types of cracks in castings

- How to operate the cooling of stainless Steel Precision Castings

- What are the principles of stainless steel precision casting method?

- What should be paid attention to when casting machine parts

- Metal Mold casting and Sand casting

- Craft measures for stainless steel precision casting

- Advanced technological process of stainless Steel Precision casting

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

What are the process measures to change stainless steel precision casting?

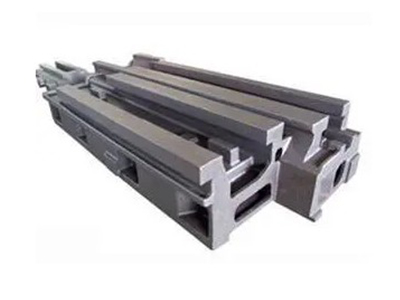

Stainless steel precision castings are widely used in injection molding machines, gas turbines, steam turbines, pumps, measuring instruments, sewing machines, office machinery and other machine parts. So what are the technological measures for changing stainless steel precision castings?

The technological measures to change stainless steel precision castings are as follows:

1. Due to the poor fluidity of molten steel, in order to avoid cold insulation and insufficient pouring, the wall thickness of stainless steel precision castings should not be less than 8mm; the structure of gating system should be simple and the section size is larger than that of cast iron; dry or hot casting mold is adopted; the pouring temperature is generally 1520 ℃ ~ 1600 ℃, because the pouring temperature is high, the superheat of molten steel is high, and the liquid state is kept for a long time.

2. Because the shrinkage of stainless steel precision casting is larger than that of cast iron, in order to avoid shrinkage, riser, cold iron and subsidy are mostly adopted in the casting process to realize sequential solidification.

Stainless steel precision casting technology is a general term of casting technology. The casting products have been used for a long time and are more heat-resistant, which can avoid distorting or ripple effects on the parts because of high temperature.