- There are several main types of cracks in castings

- The points for attention during the operation of precision casting

- Key factors of Gear Machining by stainless Steel Precision casting

- Precision processing method of pouring surfaces

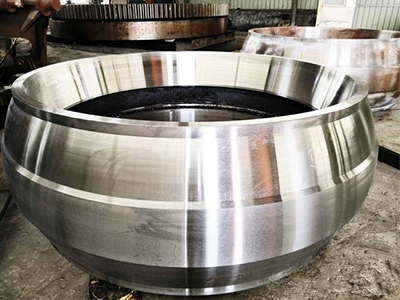

- What needs to be done before delivery of large steel castings?

- How to repair the defects of precision casting

- Influence of factors on the appearance of Roller Steel Castings

- Related requirements of Mould for Steel Castings

- What is the heat treatment process of precision casting?

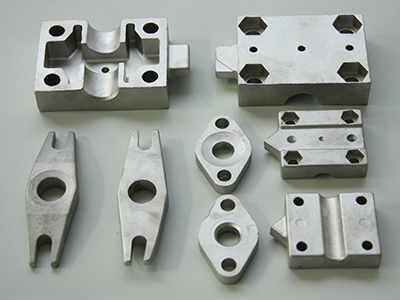

- Custom Stainless Steel Casting Manufacturing

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Key factors of Gear Machining by stainless Steel Precision casting

In the process of stainless steel precision casting gear processing, those advanced blank forming process, more stable and precise heat treatment process, and particularly suitable surface hardening treatment procedures, these are the key factors to form high-quality gears. For example, there are several key links in grinding: only by selecting the grinding wheel with sharp grinding edge and low surface stress, the grinding feed can be increased and the grinding time will be shortened. this is to improve the grinding efficiency and prolong the dressing interval of the grinding wheel to reduce the cost.

Design is not only the key step but also the initial step of stainless steel precision casting, which is also the key step for gear casting, which is related to the quality and level of cast gears. In the design stage, it is indispensable to select more suitable casting gear materials, advanced and reasonable structure design, efficient and reliable gears and bearings.

Under the premise of ensuring no grinding burn cracks and ensuring quality, it is necessary to use higher grinding parameters as much as possible to shorten the grinding time, so as to improve the grinding efficiency, increase the output, ensure its accuracy and reduce the surface roughness. By using more suitable grinding oil, under the premise of good lubrication and anti-rust, it is more beneficial to reduce the surface stress of grinding tooth surface, avoid burn cracks, reduce roughness, reduce the degree of blocking the air hole of grinding wheel, and ensure the sharpness of grinding wheel. in this way, the dressing of grinding wheel is reduced, the amount of grinding wheel is reduced and the cost is reduced.