- Introduction of cast Iron Materials

- Characteristics and calculation of gating system for Steel Castings

- Advanced technological process of stainless Steel Precision casting

- About machine tool casting understanding

- Sand casting production for large Steel Castings

- Defects of Sand Mold casting

- Features and advantages of stainless steel precision casting

- Measurement of the size of large -scale casting steel parts

- Process Classification of Precision casting

- Ductile cast iron foundry factory

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

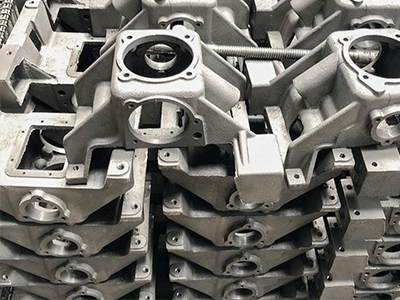

The mould used in casting and machining gears with large gear rings

When the big tooth ring casting factory produces steel castings, it uses the mold, and the mold is to directly obtain the shape and structure of the parts to be processed, and then make the material required by customers into the structure of steel castings, and then place the mold in the sand mold. The sand mold will directly form a cavity with the same structure as the large tooth ring steel castings, and the big tooth ring foundry manufacturers will pour the melted liquid into the sand mold cavity, and after the liquid is completely cooled and solidified, we will get the same structure as the large tooth ring steel casting mold.

Kunfeng cast Steel, a big tooth ring casting manufacturer, uses sodium silicate sand to cast big gears, but there are other ways to produce big gears in the industry, such as gravity casting, pressure casting and so on. No matter which method is used to process the gear, the mold will be used, so the mold has become a more important item in the whole production process. The quality of the mold and the quality of the mold technology will directly affect the quality of steel castings. And it is also of great significance for the processing level of steel castings.

With the development of society, the quality requirements of steel castings, iron castings and stainless steel parts in the market are getting higher and higher, and the demand for moulds is also increasing, especially the technological level of moulds has been significantly improved. When the large gear ring casting factory processes the gear, it can choose the appropriate mold according to the actual situation, which can not only shorten the construction period but also improve the quality of the product.