- What should be paid attention to when casting machine parts

- Gray iron casting production supplier

- What are the surface cleaning methods of stainless steel precision casting?

- The processing technology of stainless steel precision casting

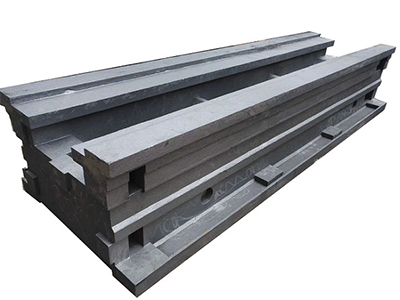

- Structural characteristics of machine tool casting

- Testing method of large Gray Iron Slag Pot Castings

- Sand casting production of large steel casting attention

- Factors affecting the accuracy of Castings

- What should I pay attention to in the production process of stainless steel casting?

- The role of heat resistance in cast steel parts

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Practical significance of pump casting to pump

Pump rolling bearing damage; roller bearing or fixed bracket cover gap is too small; pump shaft bending or two different centers; adhesive tape is too tight; oil is less or the oil is not good; the balance hole on the centrifugal impeller is blocked, and the centrifugal impeller is unbalanced, which expands the driving force to one side. Cleaning method: disassemble and replace the rolling bearing; remove the rear cover plate, modify the gasket between the fixed bracket and the seated bearing; investigate the pump shaft or adjust the coaxiality of the two shafts; appropriately adjust the tidy tightness of the blanket; fill with neat salt-free butter, salt-free butter accounts for about 60% of the clearance in the rolling bearing; eliminate blockage in the balanced hole.

There is gas in the pump body or gas in the inlet, or the bottom valve of the pump casting is not closed tightly, the diversion channel is not satisfied, the filling material of the mechanical pump is seriously leaking, and the shutoff valve or flap door is not closed tightly. Gray iron casting factory cleaning method: first put the pressure up, and then fill the pump shell with water, and then start.

At the same time, check whether the check valve is tight and whether there is any air leakage in the pipeline and connector. if air leakage is found, apply grease or blending paint to the joint after disassembly and tighten the screws. Check the skeleton sealing ring of the centrifugal pump shaft and replace the new parts if the damage is serious. Water seepage or air leakage in the pipeline. It is very likely that the nut was screwed too loose during installation. If the leakage is not serious, you can wipe the concrete in the area of air leakage or seepage, or apply cement mortar mixed with asphalted oil.

The cavitation of centrifugal pump is caused by the vaporization of water. To put it bluntly, vaporization is the whole process of the conversion of water from liquid to vapor. The vaporization of water has a certain relationship with temperature and pressure. Under a certain pressure, when the temperature rises to a certain value, the water will gradually vaporize; if at a certain temperature, when the pressure decreases to a certain value, the water will also vaporize. This pressure is called the vaporization pressure of water at that temperature. If in the whole process of fluidity, the pressure in a certain part of the area is equal to or less than the vaporization pressure relative to the temperature, the water will vaporize at that point. After vaporization, a lot of small bubbles of steam and vapor are produced.

The quality of the rotating components of the motor and the centrifugal pump is unbalanced, shoddy, the installation quality is poor, the centerline of the generator set is different, the pendulum exceeds the specified value, the impact toughness and bending stiffness of the parts are weak, the rolling bearings and sealing components are damaged, and the resonance caused by the critical speed ratio of the centrifugal pump and the resonance frequency of the generator set all cause obvious vibration and noise.