- Effect of density and Properties of large Steel Castings

- Difficulties of stainless steel precision casting processing

- Scope and method of clean up of precision casting

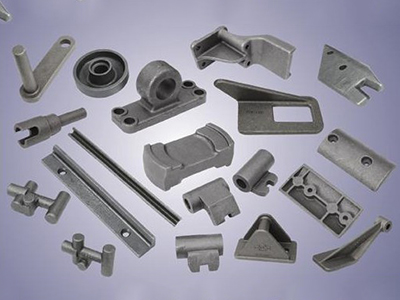

- The commonly used classification precision castings

- Application of Heat Treatment Gear Castings

- Custom Stainless Steel Casting Manufacturing

- Causes of insufficient precision specifications of precision castings

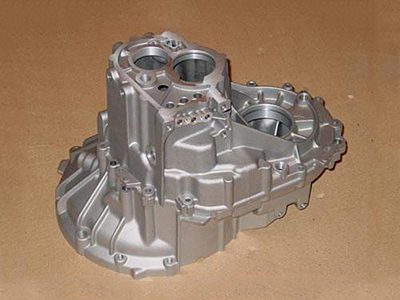

- About machine tool casting understanding

- Stainless steel precision casting is a casting process with little or no cutting

- What is the tempering treatment of stainless steel precision casting?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

The difference between Ductile Iron Castings and Gray Iron Castings

The casting process is divided into gray iron castings and nodular graphite castings according to the different uses of the castings. There is a big difference between the two.

Gray iron castings are gray iron castings and their graphite forms are flaky. Due to the existence of flake graphite, the metal matrix structure is separated and the effective load-bearing area is reduced, so its comprehensive mechanical properties are low, but its damping, wear resistance, castability and machinability are better. It is mainly used to manufacture bed, box, machine base, guideway and other parts under pressure.

Ductile iron castings have good ductility, and the morphology of graphite in nodular cast iron is spherical. Because spherical graphite has less splitting effect on metal matrix, it has high strength, plasticity and toughness, so it is widely used and can be used instead of medium carbon steel in some cases. It is mainly used to manufacture mechanical parts with complex force and heavy load, such as crankshaft, connecting rod, gear, camshaft and so on.