- Features and advantages of stainless steel precision casting

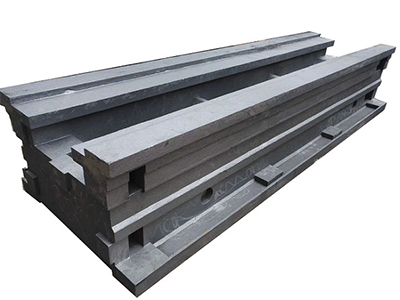

- The mould used in casting and machining gears with large gear rings

- Prevention measures to avoid defects in machine tool castings

- Application of Heat Treatment Gear Castings

- The coating and liquidity of stainless steel precision casting coatings

- What should be paid attention to when casting machine parts

- Testing method of large Gray Iron Slag Pot Castings

- What are the reasons for stainless steel casting air holes?

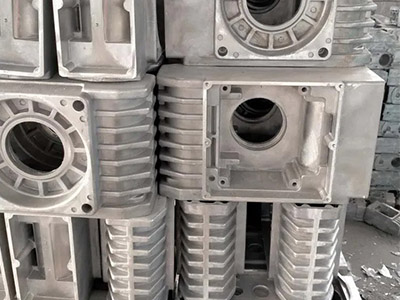

- Structural characteristics of machine tool casting

- Forging steel valve and casting steel valve

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Difficulties of stainless steel precision casting processing

The shrinkage of stainless steel precision casting is much higher than that of cast iron. in order to prevent the defects of shrinkage and porosity of castings, riser, cold iron and subsidy are mostly adopted in casting process. What are the difficulties in precision casting of stainless steel?

The difficulties of stainless steel precision casting are as follows:

1. Large cutting force and high cutting temperature: this type of material has high strength, tangential stress and plastic deformation during cutting, so the cutting force is large. In addition, the thermal conductivity of the material is poor, and the high temperature is often concentrated in the narrow area near the cutting edge of the tool, thus accelerating the tool wear.

2. Stainless steel precision casting work hardening is serious: the cutting tool has a large work hardening tendency during cutting, and the tool cutting in the work hardening area shortens the tool life.

3. The tool wear is accelerated, and the material generally contains high melting point elements, high plasticity and high cutting temperature, which speeds up the tool wear, sharpens the tool and changes the tool frequently, thus affecting the production efficiency and increasing the tool cost.

4. Stainless steel is easy to stick to the knife in precision casting: no matter any stainless steel, it has the characteristics of strong and tough chip and high cutting temperature.

In the process of stainless steel precision casting, the solidified materials such as liquid at room temperature are directly poured into the mold of its specific shape, and the processing method of solidification forming is mostly solid and then directly heated into liquid metal.