- Custom Stainless Steel Casting Manufacturing

- What is the technological process of stainless steel precision casting?

- Where is the large-scale cast steel parts used?

- Ductile cast iron foundry factory

- Scope and method of clean up of precision casting

- Advanced technological process of stainless Steel Precision casting

- Steel die casting process

- Application of Heat Treatment Gear Castings

- Temperature control of stainless steel precision casting

- What are the determination methods of stainless steel precision casting?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

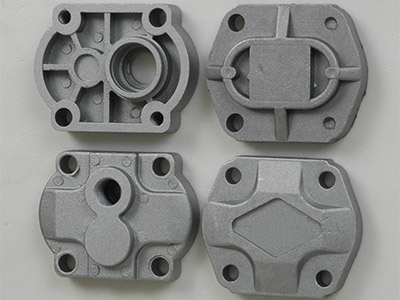

Technical requirements and material selection of precision casting

In the process of manufacturing precision castings, after solidifying the liquid at room temperature directly, the material is poured into the mold of its specific shape and the processing method of its solidification forming. Precision casting is mostly solid and then directly heated into liquid metal, the metal materials used are lead, copper, iron, aluminum and other materials.

The materials of moulds in precision casting can be metal, sand or ceramics, which need to be used according to their different requirements, and the methods will be different. This method of production is called castings, and the metal mold can be gray iron or ductile iron.

Precision casting can produce complex parts in the process of processing, especially the complex cavity blank, which is widely used in use. generally speaking, the metal materials commonly used in industry can be cast. The raw material source of precision casting is very extensive, and the price of the product is very low in the process of use. the shape and size of equipment scrap, scrap and chip castings are very close to those of parts, which can effectively reduce the amount of cutting. this belongs to less cutting.

A large number of precision casting production effectively creates favorable conditions for the factory, and a very advanced technical modeling method is adopted in the process of use, and the air impact molding line of the product can meet the requirements of fast and high-precision modeling production line. the core-making method can choose its shell core and other efficient core-making methods.