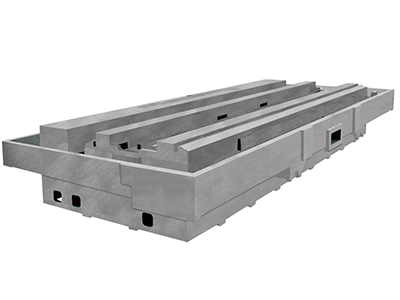

- Sand casting production for large Steel Castings

- The points for attention during the operation of precision casting

- Key factors of Gear Machining by stainless Steel Precision casting

- How are Stainless Steel Castings Made?

- How to control the temperature of stainless steel precision casting?

- What is the heat treatment process of precision casting?

- What are the common stainless steel precision castings?

- What are the models of ductile iron castings?

- Precision requirements and cost of Precision Castings

- What should I pay attention to in the production process of stainless steel casting?

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Why should the quality of steel casting pay attention to good molds

Steel casting manufacturers often say that if you want to cast steel with good quality, mold is very important to pay attention to. That is because of the strong plasticity and wide use of casting, manufacturers have their own unique production process in casting, which is roughly the design of drawings, mold design, pouring, mold opening, processing. Mould is an important part of casting production, which needs to pay attention to the problem is?

It is necessary to pay attention to the mold temperature in the casting, because the mold is not preheated before production, and it is easy to appear sudden cooling phenomenon in the pouring molten steel filling, resulting in the sudden increase of the temperature between the inner and outer layers of the casting mold, leading to cracking and quality problems; After the steel casting mold is preheated, the manufacturer will arrange casting and filling. Due to the high temperature and pouring speed of molten steel, it will have a very large impact on the mold, and chemical reactions of molten steel, gas and impurities will occur in this casting, which will cause cracks in the casting and seriously lead to scrapping. Now let's talk about mold opening, mold opening is the process of casting core pulling, etc., in this process is not well operated, will lead to casting deformation, etc., resulting in quality problems of casting. The above is the need to pay attention to the mold, in daily production to do a good job of prevention, if unfortunately, the manufacturer should do a good job of how to remedy.

In casting production, nothing can be ignored. Steel casting manufacturers should be responsible for every step of steel casting production, so that the quality of steel casting can be guaranteed.