- Gray iron casting production supplier

- How to clean the surface of stainless steel castings

- Effect of density and Properties of large Steel Castings

- Metal Mold casting and Sand casting

- Comparison between Die Casting and Sand Casting

- What should be avoided during the casting process of precision casting manufacturers?

- The points for attention during the operation of precision casting

- There are several main types of cracks in castings

- Features and advantages of stainless steel precision casting

- Measurement of the size of large -scale casting steel parts

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

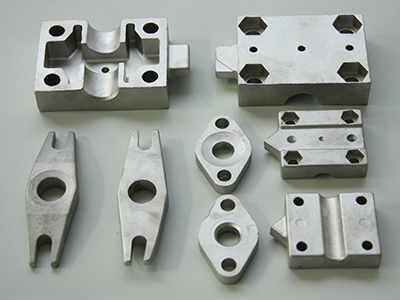

How are Stainless Steel Castings Made?

Stainless steel casting involves creating an original wax model, building the image with plaster and successive layers until a strong shell surrounds the model. After melting the wax, pour the molten stainless steel into the mold to create a perfect replica of the original wax pattern. Stainless steel casting provides economical undercutting, high resolution, sophisticated detail and smooth surface finish compared to machining separations.

In most cases, stainless steel casting is the only way the part can be made economically.