- The Investment casting method can save time

- Matters needing attention in detail handling of stainless Steel Castings

- What are the processing steps of stainless steel precision casting?

- Brief introduction of centrifugal ductile cast iron pipe

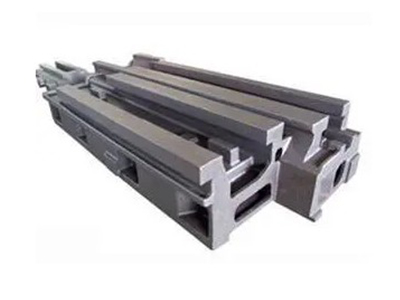

- Buy cast iron machine tools pay attention to quality

- Industrial indicators of quenched castings

- The characteristics of precision casting

- Scope and method of clean up of precision casting

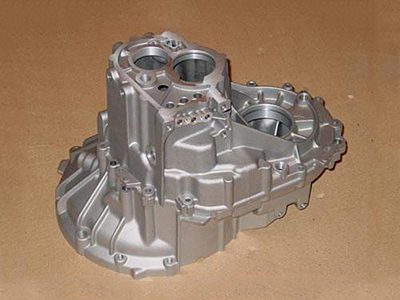

- What are the common stainless steel precision castings?

- Calculation method and proportion of casting riser design

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

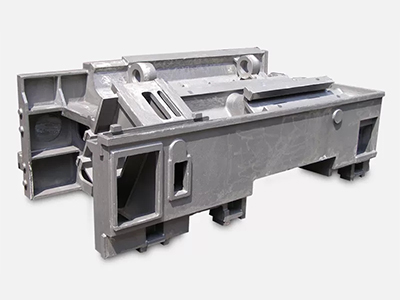

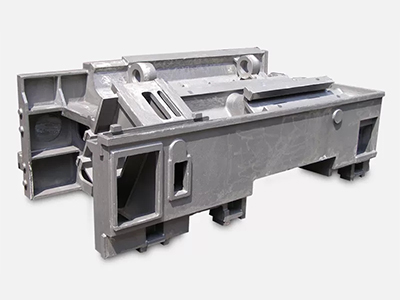

Causes of the formation of two stress of machine tool casting

First of all, let's take a look at the properties of the sand that make up the machine tool castings, the properties and compositions of the sand: the main force of the performance requirements of the sand (including core sand), good air permeability, fire resistance, preference, fluidity, compactness and folding, etc.; sand, resin, synthetic fats and vegetable oils, etc., are called.

In order to further shape some properties of (core) sand, some additional conditions are often added to the molding (core) sand, such as coal, sawdust, paper pulp.

Next, let's take a look at the formation of two stresses in machine tool castings during die casting:

Thermal stress: uneven casting thickness, different cooling rate and inconsistent shrinkage.

Plastic state: during the solid cooling stage when the metal is higher than the recrystallization temperature, the metal is deformed by force, resulting in work hardening, which is offset by recrystallization hardening, and the internal stress disappears by itself. (to put it simply, it is in a state of yield and there is no stress in force-deformation.).

Elastic state: below the recrystallization temperature, the metal undergoes elastic deformation under the action of external force, and the stress continues to exist after deformation.

For example: a) at the beginning of solidification, the coarse and fine parts are in a plastic state and there is no internal stress.

Because the cooling speed of the two bars is different, the thin rod is fast and the contraction is large, so it is limited by the thick rod, it can not contract freely, it is relatively elongated, and the thick rod is relatively compressed, resulting in the same contraction of the two bars.

B) the cooling rate of the thin rod is large, such as the elastic stage, while the thick rod is still in the plastic stage, and the plastic shrinkage occurs with the shrinkage of the thin rod, and there is no stress.

C) the shrinkage of the thin rod stops first, the coarse rod continues to contract, pressing the thin rod, while the thin rod prevents the contraction of the coarse rod, and at room temperature, the coarse rod is subjected to tensile stress (+), (-).

Thus it can be seen that the greater the temperature difference of each part, the greater the thermal stress, the slower cooling part forms the tensile stress, and the faster cooling part forms the compressive stress.