- High speed train carbon steel connecting rod castings

- Carbon Steel Auto Parts Precision Casting

- Carbon steel automobile brake system parts casting

- Automobile carbon steel precision parts castings

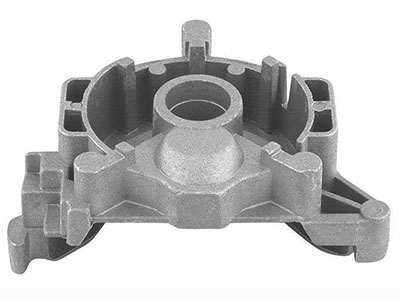

- Carbon steel precision casting for automobile balance frame

- Carbon Steel Ship Castings

- Stainless Steel Brake Disc Casting Processing

- Automobile and motorcycle stainless steel parts precision castings

- Automobile stainless steel gimbal precision casting

- Stainless steel hinge precision casting

- Stainless Steel Ship Castings

- Stainless Steel Auto Parts Castings

- Automobile suspension alloy steel bracket precision casting

- Railway Press Plate Alloy Steel Castings

- Alloy Steel Ship Castings

- High speed train alloy steel connecting rod castings

- Alloy Steel Auto Parts Precision Castings

- Automobile balance frame alloy steel precision casting

- Ship accessories casting

- Low Speed Lever Precision Casting

- Auto parts precision castings

- Knocking wrench precision casting

- Powerful wrench precision castings

- Railway accessories casting

Investment Casting Process

Call : +86 13390692151

sale@kfqizhongji.com

When wax is used to make the shape, investment casting is also called "lost wax casting". Investment casting usually refers to a casting scheme in which a shape is made of fusible materials, a shell is made of refractory materials on the surface of the shape, and then the shape is melted to discharge the shell, so as to obtain a casting shape without parting surface, which can be filled with sand after roasting at high temperature. Because the appearance is widely made of wax material, investment casting is often called "lost wax casting". The types of alloys that can be produced by investment casting are carbon steel, alloy steel, heat-resistant alloy, stainless steel, precision alloy, permanent magnet alloy, bearing alloy, copper alloy, aluminum alloy, titanium alloy and ductile iron, etc.

Advantages:

High dimensional accuracy. As far as CT4-6 (sand casting for CT10~13, die casting for CT5~7); It can improve the utilization rate of metal materials. Investment casting can significantly reduce the processing amount of the forming surface and matching surface of the product, and save the consumption of the processing table and the cutting tool materials; It can improve the similarity between the blank and the parts, and bring great convenience to the structural design of the parts. Casting complex shape casting investment casting can cast the shape of the very complex castings, can also cast wall thickness of 0.5mm, weight as small as 1g of casting, can also cast combined, integral casting; It is not limited by alloy materials. The investment casting method can cast carbon steel, alloy steel, ductile iron, copper alloy and aluminum alloy castings, but also can cast high temperature alloy, magnesium alloy, titanium alloy and precious metal materials castings. For alloy materials that are difficult to forge, weld and cut, it is especially suitable for casting by investment casting method; High production flexibility and adaptability Investment casting is not only suitable for mass production, but also for small batch production and even single production.

Disadvantages and Limitations:

The casting size should not be too large. The cooling rate of the casting is slow. Investment casting in all the blank forming methods, the process is complex, casting cost is also high, but if the product selection is appropriate, the part design is reasonable, the high casting cost due to the reduction of cutting processing, assembly and saving metal materials and other aspects are compensated, investment casting has good economy.