- Factors affecting machine tool castings

- How to control the temperature of stainless steel precision casting?

- Application fields and products of iron castings

- Factors that cause precision casting size defects

- Causes of insufficient precision specifications of precision castings

- Requirements for precision casting

- Application of Heat Treatment Gear Castings

- Precision processing method of pouring surfaces

- Stainless steel precision forged process measures below

- Ductile cast iron foundry factory

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

Stainless steel precision forged process measures below

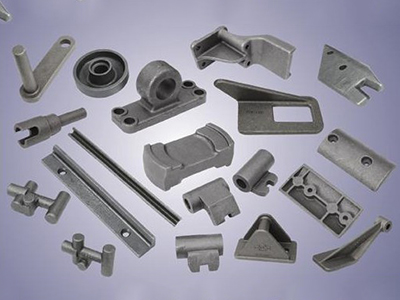

Stainless steel precision forging castings are widely used in injection molding machines, gas turbines, steam turbines, compressors, valve parts, pumps, measuring instruments, sewing machines, weapons, office machines and other machine parts.

The technological measures for precision forging of stainless steel are as follows:

1. Due to the poor activity of molten steel, in order to prevent cold insulation and insufficient pouring of stainless steel castings, the wall thickness of stainless steel castings can not be less than 8 mm; the layout of the gating system is simple, and the section size is larger than that of cast iron; dry or hot casting moulds are adopted; properly improve the pouring temperature, usually 1520 °~ 1600 ℃, because the pouring temperature is high, the superheat of molten steel is large, and the liquid state is kept for a long time.

However, if the pouring temperature is too high, it will cause coarse grains, hot cracks, pores, sticking sand and so on.

Therefore, the pouring temperature of ordinary small, thin-walled and complex castings is about + 150 ℃ of steel, while the pouring temperature of large and thick-walled castings is higher than 100 ℃.

2. Because the forging compression of stainless steel castings is much higher than that of cast iron, in order to prevent the shrinkage of stainless steel castings, riser, cold iron and subsidy are mostly used in the forging process to achieve successive condensation.

The benefits of precision forging of stainless steel are as follows.

1. Less restrictions on forging materials, such as aluminum alloy, magnesium alloy, titanium alloy, copper alloy, all kinds of steel, cobalt-based, nickel-based heat resistance.

2.The production style of complex workpieces, good dimensional accuracy, less cutting.

3. Reduce material extravagance and can be produced on a large scale.

Stainless steel precision forging is a forging process with little or no cutting, which is an excellent technology in the forging industry, and its use is very extensive.

The reasons for forging air holes in stainless steel are as follows:

The poor air permeability of the coating is probably insufficient under negative pressure, and the air permeability of the filling sand is poor, so the gas and residue in the mold cavity can not be extruded in time to form pores under the filling pressure.

The pouring speed is too slow to fill the sprue cup, expose the sprue, get involved in the air, inhale the slag, and form entrapped pores and slag holes.

A large number of gases and residues produced by the gasification of the foam mold can not be squeezed out of the casting in time, and the drying up of the dry sand added by the foam and coating layer is poor, under the high temperature entanglement of the liquid alloy, the important reason for the formation of pores is that a large amount of hydrogen and oxygen are cracked into the casting.

The continuous sealing between the sprue cup and the sprue and the gating system is not good, especially the continuous sealing between the sprue and the sprue cup, which can be calculated and explained by Bernoulli equation.

The filling speed of stainless steel forging metal liquid is higher than that of foam gasification concession and gas extrusion speed, and the inner wall smoke black release pore is formed by re-gasification in the metal liquid.