- What should be avoided during the casting process of precision casting manufacturers?

- How to avoid pollution in stainless steel castings

- What are the common stainless steel precision castings?

- Precision requirements and cost of Precision Castings

- Stainless steel precision casting is a casting process with little or no cutting

- Factors affecting precision casting accuracy

- Inspection Standard and testing content of Steel Castings

- It is recommended that you choose castings like this

- How to make the appearance of large cast steel parts better

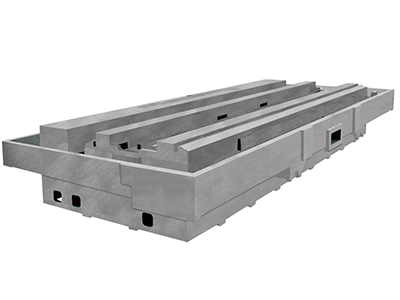

- Structural characteristics of machine tool casting

- Call : +86 13390692151

- sale@kfqizhongji.com

-

Room 1, No. 21, Chaoying East Road, Zhoushi,

Kunshan City, Jiangsu Province, China

How to adjust the furnace fire cast by stainless steel?

Stainless steel precision casting is a casting process with little or no cutting, and it is an excellent technology in the casting industry. it is widely used, not only for various types and alloys. So we all know how to adjust the stainless steel casting furnace fire?

Stainless steel casting is a casting method, which can obtain relatively accurate appearance and high casting precision. The broader method is: first make abrasives according to commodity regulations, casting wax, get the initial wax mold; repeated coating and sand process, solidification shell and drying; then melt the internal wax mold, dewaxing, and get a concave mold; roasting shell to obtain sufficient compressive strength; stainless steel casting metal composite materials; shelled sand to obtain high-precision finished products, heat treatment process and cold processing according to the needs of the commodity. The following is how to adjust the fire of precision castings.

Stainless steel precision casting moderately increases the casting temperature, yes. Although the liquid collection increases with the increase of casting temperature, it is beneficial to clean up the slag and air orifice. Although the depth adjustment of casting triangle white mouth is very traditional, it is easy to use, which is very beneficial to the rapid distinction between professional technicians and employees in the actual operation outside the furnace. If the size of the triangular white mouth is related to the creative effect, whole phase structure, thermal analysis curve and physical properties, it is beneficial to the on-line adjustment of the quality of cast iron.

When adjusting the furnace fire of stainless steel casting, we should all adjust the furnace fire of stainless steel casting according to the above adjustment method.